3D Printed Figure Eight Mechanism: A Compact Design Guide

The 3D printed figure eight mechanism is a fascinating and compact design that has gained popularity among engineers, hobbyists, and makers. Its unique motion and space-saving structure make it ideal for applications ranging from robotics to kinetic art. In this guide, we’ll walk you through the process of designing and 3D printing your own figure eight mechanism, ensuring it’s both functional and efficient. Whether you’re a beginner or an experienced designer, this post will provide valuable insights and practical tips to bring your project to life, (3D printing tips, compact mechanism design, figure eight mechanism applications)

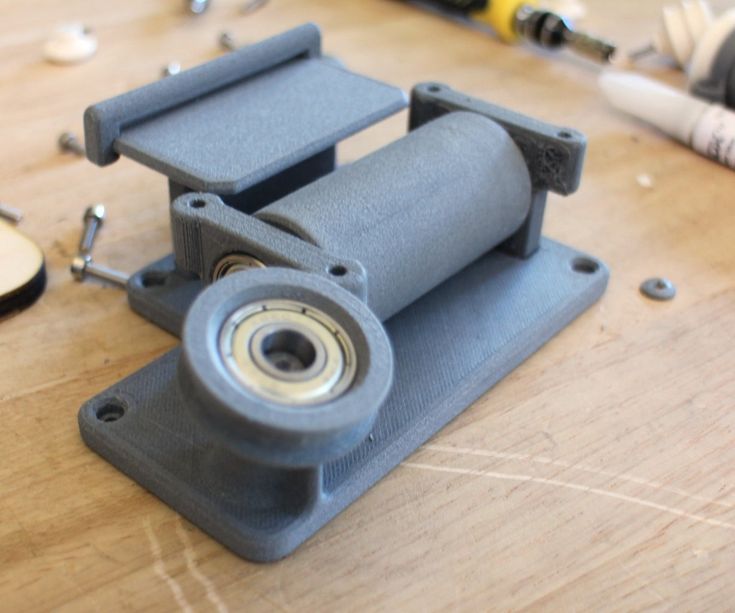

Understanding the Figure Eight Mechanism

The figure eight mechanism, also known as a lemniscate mechanism, produces a smooth, continuous motion in the shape of a figure eight. This design is particularly useful in applications requiring precise, repetitive movements in a limited space. Its compact nature makes it a favorite for 3D printing projects, as it minimizes material usage while maximizing functionality.

📌 Note: Ensure your design accounts for the mechanism’s range of motion to avoid interference between components.

Designing Your 3D Printed Figure Eight Mechanism

Key Components

- Crank Arm: Drives the mechanism’s motion.

- Linkages: Connect the crank arm to the output component.

- Output Component: Follows the figure eight path.

Design Tips

- Use CAD software like Fusion 360 or Tinkercad for precise modeling.

- Incorporate clearances between moving parts to prevent friction.

- Optimize for 3D printing by adding supports and avoiding overhangs.

✨ Note: Test your design virtually before printing to identify potential issues.

3D Printing and Assembly

Printing Guidelines

| Material | Layer Height | Infill |

|---|---|---|

| PLA | 0.2 mm | 20% |

| PETG | 0.2 mm | 30% |

Assembly Steps

- Clean printed parts to remove supports and imperfections.

- Assemble the crank arm and linkages, ensuring smooth movement.

- Attach the output component and test the mechanism.

🔧 Note: Use lightweight materials for better performance and reduced wear.

Applications and Customization

The figure eight mechanism can be adapted for various uses, including robotic arms, kinetic sculptures, and automation systems. Customize your design by adjusting the size, material, and motion range to suit your specific needs.

For commercial applications, consider scaling up production using 3D printing services or investing in high-precision printers for consistent results, (robotic arm design, kinetic sculpture ideas, automation system components)

Creating a 3D printed figure eight mechanism is a rewarding project that combines creativity and technical skill. By following this guide, you’ll be able to design, print, and assemble a compact and efficient mechanism tailored to your needs. Whether for personal or commercial use, this design opens up endless possibilities for innovation and experimentation.

What materials are best for 3D printing a figure eight mechanism?

+

PLA and PETG are ideal due to their balance of strength and ease of printing. PLA is beginner-friendly, while PETG offers better durability.

How can I reduce friction in the mechanism?

+

Incorporate clearances in your design and use lubricants like silicone spray or PTFE coatings on moving parts.

Can I scale the design for larger applications?

+

Yes, but ensure structural integrity by increasing wall thickness and using stronger materials like ABS or nylon.