ASA Melting Point: Essential Facts and Applications

The ASA melting point is a critical property in material science and chemistry, offering insights into the thermal stability and purity of substances. Understanding this concept is essential for researchers, manufacturers, and anyone involved in material testing. Whether you’re analyzing polymers, pharmaceuticals, or organic compounds, the ASA melting point plays a pivotal role in quality control and application development.

What is ASA Melting Point?

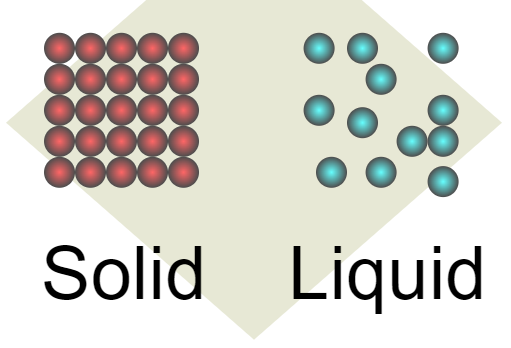

The ASA melting point refers to the temperature at which a substance transitions from a solid to a liquid state. For ASA (Acrylonitrile Styrene Acrylate), a common thermoplastic, this property is crucial for determining its suitability in various applications. The melting point indicates the material’s thermal resistance and is often used to assess purity and consistency.

Why is ASA Melting Point Important?

The ASA melting point is a key parameter in material science for several reasons:

- Quality Control: Ensures the material meets industry standards.

- Application Suitability: Determines if ASA can withstand specific environmental conditions.

- Purity Assessment: Helps identify contaminants or impurities in the material.

💡 Note: Accurate measurement of the ASA melting point requires calibrated equipment and controlled conditions.

How to Measure ASA Melting Point

Measuring the ASA melting point involves precise techniques and tools. Here’s a step-by-step guide:

1. Prepare the Sample: Ensure the ASA material is free from moisture and impurities.

2. Use a Differential Scanning Calorimeter (DSC): This device measures heat flow and identifies the melting point.

3. Record Data: Note the temperature at which the phase transition occurs.

Applications of ASA with Known Melting Point

ASA’s melting point makes it ideal for various industries:

- Automotive: Used in interior and exterior components due to its heat resistance.

- Electronics: Ideal for enclosures and housings that require thermal stability.

- Consumer Goods: Applied in products like appliances and toys for durability.

| Industry | Application |

|---|---|

| Automotive | Interior Components |

| Electronics | Enclosures |

| Consumer Goods | Appliances, Toys |

Factors Affecting ASA Melting Point

Several factors can influence the ASA melting point:

- Molecular Weight: Higher molecular weight often results in a higher melting point.

- Crystallinity: The degree of crystallization affects thermal behavior.

- Additives: Fillers or stabilizers can alter the melting point.

Checklist for ASA Melting Point Analysis

- Calibrate Equipment: Ensure DSC or other tools are accurately calibrated.

- Prepare Samples: Remove moisture and impurities for precise results.

- Record Conditions: Note ambient temperature and pressure during testing.

- Compare Results: Cross-reference with known standards for validation.

To summarize, the ASA melting point is a vital characteristic that influences material selection and application. By understanding its significance and measurement techniques, industries can ensure optimal performance and quality. Whether for research or manufacturing, mastering this concept is key to leveraging ASA’s full potential.

What is the typical ASA melting point range?

+The ASA melting point typically ranges between 90°C to 110°C, depending on the material composition.

How does molecular weight affect ASA melting point?

+Higher molecular weight generally increases the melting point due to stronger intermolecular forces.

Can additives change the ASA melting point?

+Yes, additives like fillers or stabilizers can alter the melting point, often lowering it slightly.

ASA melting point analysis,material science,thermoplastic applications,quality control in manufacturing,thermal stability testing