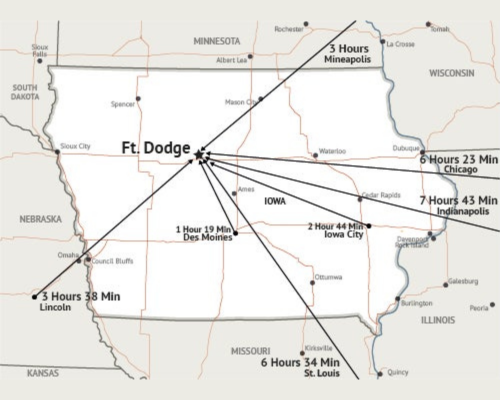

Fort Dodge Asphalt: Iowa's Reliable Paving Solution

When it comes to durable and reliable paving solutions in Iowa, Fort Dodge Asphalt stands out as a trusted name. Whether you're looking to pave a driveway, parking lot, or roadway, understanding the benefits and process of asphalt paving is essential. This blog will guide you through why Fort Dodge Asphalt is Iowa's go-to choice, offering both informative and commercial insights to meet your needs. From the advantages of asphalt to the paving process, we’ve got you covered. (asphalt paving, Iowa paving solutions, Fort Dodge Asphalt)

Why Choose Fort Dodge Asphalt?

Fort Dodge Asphalt has built a reputation for delivering high-quality paving solutions across Iowa. Here’s why it’s the preferred choice:

- Durability: Asphalt is known for its long-lasting performance, even in Iowa’s harsh weather conditions.

- Cost-Effective: Compared to other materials, asphalt is budget-friendly without compromising quality.

- Quick Installation: The paving process is faster, minimizing disruption to your daily activities.

- Eco-Friendly: Asphalt is recyclable, making it a sustainable choice for environmentally conscious projects.

📌 Note: Regular maintenance can extend the lifespan of your asphalt pavement significantly. (asphalt durability, cost-effective paving, eco-friendly asphalt)

The Asphalt Paving Process

Understanding the paving process ensures you know what to expect when working with Fort Dodge Asphalt. Here’s a breakdown:

- Site Preparation: The area is cleared, graded, and compacted to create a stable base.

- Base Installation: A layer of crushed stone or gravel is added for added strength.

- Asphalt Laying: Hot asphalt is poured and spread evenly using specialized equipment.

- Compaction: The asphalt is compacted to ensure a smooth and durable surface.

- Finishing Touches: Edges are trimmed, and the surface is checked for quality.

📌 Note: Proper drainage is crucial during site preparation to prevent water damage. (asphalt paving process, site preparation, asphalt compaction)

Benefits of Asphalt for Iowa Residents

Iowa’s climate demands a paving material that can withstand extreme temperatures and weather conditions. Here’s why asphalt is ideal:

| Benefit | Description |

|---|---|

| Weather Resistance | Asphalt expands and contracts with temperature changes, reducing cracks. |

| Snow and Ice Management | Dark asphalt surfaces melt snow and ice faster, improving safety. |

| Smooth Surface | Provides a comfortable ride for vehicles and reduces wear and tear. |

For Iowa homeowners and businesses, these benefits make asphalt the smart choice. (weather-resistant asphalt, snow management, smooth pavement)

How to Maintain Your Asphalt Pavement

To maximize the life of your asphalt, follow these maintenance tips:

- Regular Cleaning: Remove debris and dirt to prevent surface damage.

- Sealcoating: Apply a sealant every 2-3 years to protect against UV rays and water.

- Crack Repair: Fill cracks promptly to prevent water infiltration and further damage.

- Professional Inspections: Schedule regular check-ups to catch issues early.

Proper maintenance ensures your asphalt remains in top condition for years. (asphalt maintenance, sealcoating, crack repair)

Fort Dodge Asphalt is Iowa’s reliable paving solution, offering durability, affordability, and sustainability. Whether you’re a homeowner or business owner, choosing asphalt ensures a smooth, long-lasting surface that can withstand Iowa’s challenging climate. By understanding the paving process and maintaining your asphalt properly, you’ll enjoy a high-quality pavement for years to come. Trust Fort Dodge Asphalt for all your paving needs and experience the difference. (reliable paving, Iowa asphalt solutions, Fort Dodge Asphalt)

How long does asphalt paving last in Iowa?

+

With proper maintenance, asphalt paving can last 15-20 years in Iowa’s climate.

Is asphalt paving environmentally friendly?

+

Yes, asphalt is recyclable and requires less energy to produce, making it an eco-friendly option.

How often should I sealcoat my asphalt driveway?

+

Sealcoating should be done every 2-3 years to protect against weather damage and UV rays.