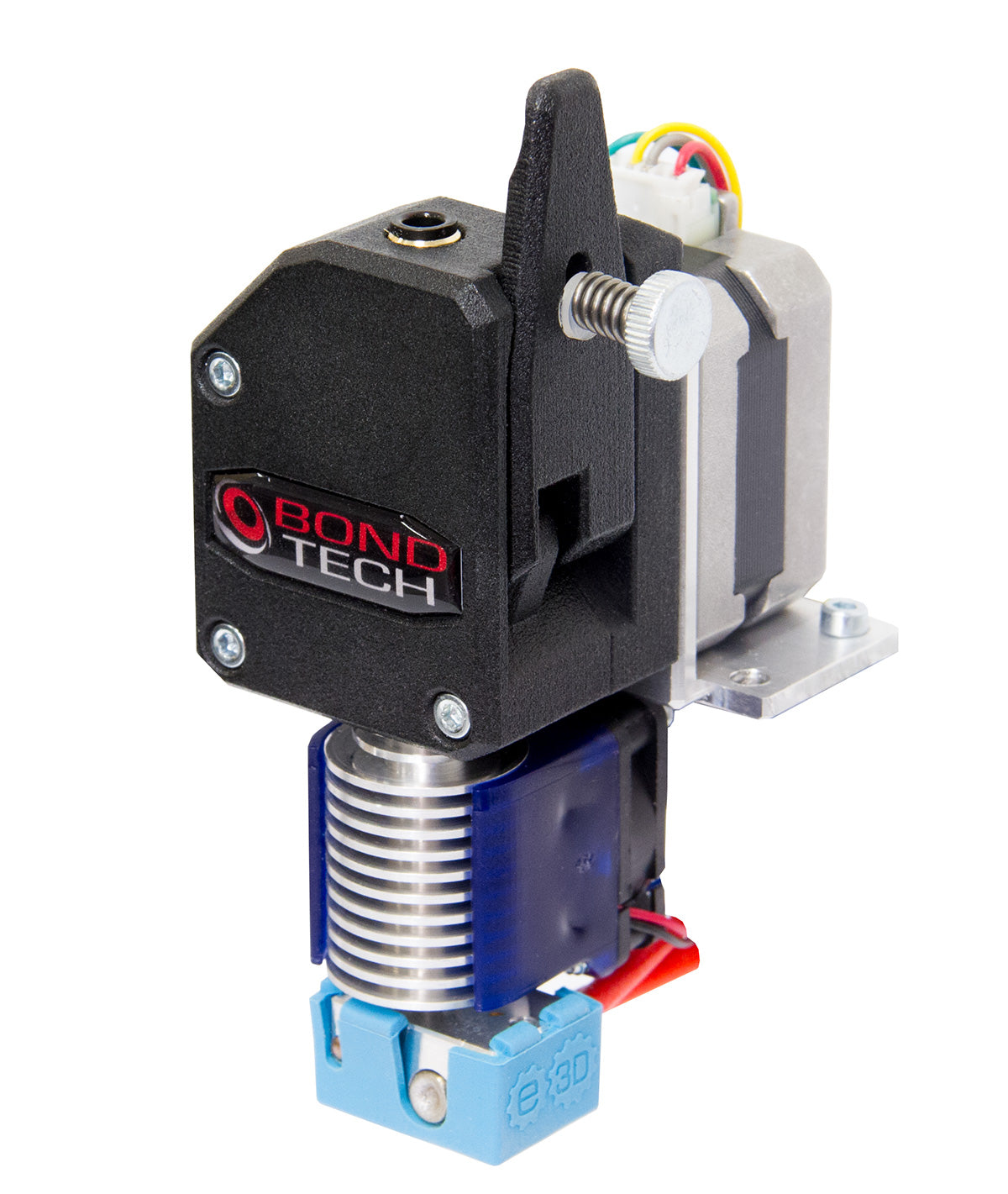

Upgrade Your Orbiter with Bondtech Gears for Precision Printing.

<!DOCTYPE html>

If you’re looking to enhance the performance of your 3D printer, upgrading your Orbiter with Bondtech gears is a game-changer. Bondtech gears are renowned for their precision, durability, and ability to improve filament feeding, resulting in smoother and more accurate prints. Whether you’re a hobbyist or a professional, this upgrade can significantly elevate your printing experience. Below, we’ll guide you through the benefits, installation process, and essential tips to ensure a successful upgrade.

Why Choose Bondtech Gears for Your Orbiter?

Bondtech gears are designed to provide superior filament control, reducing the risk of clogs, slips, and uneven extrusion. Their dual-drive system ensures consistent feeding, making them ideal for printing with flexible or abrasive materials. By upgrading your Orbiter with Bondtech gears, you can achieve:

- Improved Print Quality: Enhanced precision and reduced layer inconsistencies.

- Increased Reliability: Minimized filament jams and printing interruptions.

- Material Versatility: Better handling of exotic filaments like TPU, PETG, and composites.

3D printing upgrades,Orbiter extruder,Bondtech dual-drive system

Step-by-Step Guide to Upgrading Your Orbiter with Bondtech Gears

Tools and Materials Needed

Before you begin, gather the following:

- Bondtech gears kit compatible with your Orbiter model

- Screwdrivers (Phillips and flathead)

- Pliers or needle-nose pliers

- Lubricant (optional, for smooth operation)

Installation Process

- Disassemble the Orbiter Extruder: Carefully remove the original gears and any retaining components.

- Install Bondtech Gears: Align the new gears according to the manufacturer’s instructions and secure them in place.

- Reassemble the Extruder: Ensure all parts are properly seated and tightened.

- Test the Setup: Load filament and perform a test print to verify smooth operation.

💡 Note: Always refer to the Bondtech gears manual for model-specific instructions.

Orbiter extruder upgrade,Bondtech installation,3D printer maintenance

Tips for Maximizing Your Bondtech Gear Upgrade

- Calibrate Your Printer: Adjust settings like retraction and flow rate to optimize performance.

- Regular Maintenance: Clean the gears periodically to prevent dust and debris buildup.

- Experiment with Materials: Test different filaments to explore the full potential of your upgraded Orbiter.

3D printing tips,Bondtech maintenance,Orbiter calibration

Checklist for Upgrading Your Orbiter with Bondtech Gears

| Step | Details |

|---|---|

| 1. Gather Tools | Screwdrivers, pliers, lubricant |

| 2. Disassemble Extruder | Remove original gears carefully |

| 3. Install Bondtech Gears | Follow manufacturer’s instructions |

| 4. Reassemble and Test | Ensure smooth filament feeding |

Orbiter upgrade checklist,Bondtech installation steps,3D printer tools

Upgrading your Orbiter with Bondtech gears is a straightforward yet impactful way to enhance your 3D printing capabilities. With improved precision, reliability, and material compatibility, you’ll notice a significant difference in your prints. Follow the steps and tips outlined above to ensure a successful upgrade and enjoy the benefits of a high-performance extruder system.

What are the main benefits of upgrading to Bondtech gears?

+Bondtech gears improve filament feeding precision, reduce clogs, and enhance compatibility with various materials, resulting in higher print quality.

Is the Bondtech gear upgrade compatible with all Orbiter models?

+Bondtech offers kits compatible with most Orbiter models, but always check compatibility before purchasing.

How often should I maintain my Bondtech gears?

+Regular cleaning every few months and occasional lubrication will keep your Bondtech gears in optimal condition.